Welcome to Henan Zhongyide Intelligent Technology Co., LTD

Welcome to Henan Zhongyide Intelligent Technology Co., LTD

Product Center

CONTACT US

Product Introductions

VZY ultrafine vertical mill is the first kind of secondary classification technology , which absorbing the ultrafine vertical mill technology from Europe, America and Taiwan, and using high-quality wear-resistant parts,at the same time depending many years’ experience. So the product fineness can be up to 400~6000 mesh .

Ultrafine Vertical Mill Application

VZY series vertical ultrafine powder vertical roller mill is widely used to grind all kinds of Metallic and non-metallic minerals such as calcite, marble, limestone, barite, talc, kaolin, dolomite, wollastonite, gypsum, feldspar, phyllite, alumina, wollastonite, bamboo wood, silica black, sericite, barium sulfate, quartz sand, heavy calcium carbonate, light calcium carbonate, steel slag, furnace slag, water slag,etc.

Working principle

The main motor drives the grinding disc to rotate through the reducer, and the small materials less than 10mm enter the vertical mill’s input through the screw conveyor, and fall to the center of the grinding disc under the action of gravity, while the air generated by the fan enters the main machine from the air intake. Under the action of centrifugal force, the materials move evenly from the center of the disc to the edge, through the roller table area on the disc, then are rolled by the mill roller, the larger materials are directly crushed, the smaller materials are extruded in the material layer, and is crushed between grains again. The pulverized materials are carried upward by the strong air flow, and rise with the air flow into the powder selection system above the mainframe for classification. Under the action of the classifier rotor blade, the coarse particles are knocked down by the blade and returned to the grinding disc for grinding. The qualified fine powder will be brought out of the powder selection system with the negative pressure air flow, entering the dust removal equipment, and then collected by the powder collector, that is, the fineness product. In addition, the rest of the large particle materials and debris will fall into the lower chamber of the mill during grinding, and will be scraped into the slag discharge port by the scraper, effectively ensuring the quality of the finished product.

1.The fineness powder is diverse. Ultrafine Powder Vertical Roller Mill equipped with turbine air classifier, so that it can produce a large particle size range. The fineness powder of 2um is up 10%-60%, the final powder of 8.5μm can be directly produced by mill when passing rate is D97 .

2.With optimized process design. The VZY series ultra-fine vertical mill consumes less energy than similar vertical mills with optimized process design .

3.The ultrafine powder produced by the main machine has the advantages of narrow particle size distribution. When the powder of 2um, the mesh is adjustable and controllable. The Ultrafine Powders are widely used, such as artificial granite, plastic masterbatch, PVC pipe, wire and cable, diaper, non-woven fabrics and other industries and have the advantages of good activation effect and low oil absorption value.

4. The mill efficiency is higher than internal grinding mill and the capacity is improved 15%~30% at using the upgrading wheels,disc,diversion system and internal circulation system.

5.The mainframe and the main wear-resistant parts are all made by imported wear-resistant materials, increasing the service life of the grinding machine and reducing the maintenance cost.

6.More environmental:The improved mill’disc can operate under low vibration, and the SRM series grinding machine has lower noise compared with home and outside brands.

7. In the grinding process, the powder is treated radding grinding aid to improve the added value of the product.

8. The system uses PLC control with Flash real-time display, and can be perfectly connected with the continuous modification machine control system, whcih has realized the higher degree of artificial intelligence.

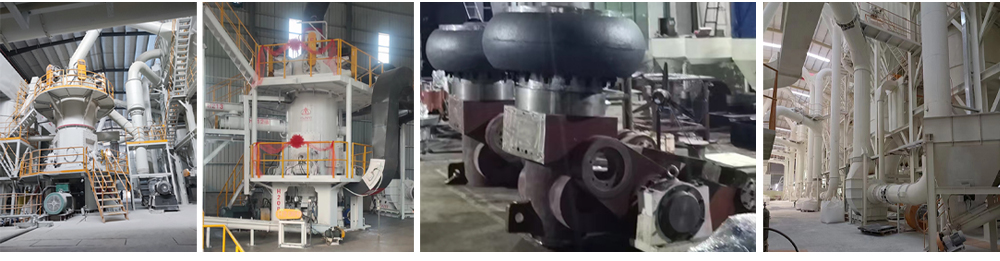

Customer Site Map

Technical data(take calcite mineral as the grinding material)

model | VZK-750 | VZK-1100 | VZK-1200 | VZK-1400 | |

Less than 2μm=33% CAPACITY(t/h) | 1.0-1.2 | 6~8 | 11~13 | 12~14 | 14~16 |

Less than 2μm=40% CAPACITY(t/h) | 0.5-0.6 | 4~6 | 8~9 | 11~13 | 12~14 |

Less than 2μm=50% CAPACITY(t/h) | 0.2-0.3 | 2~3 | 5~6 | 7~8 | 9~10 |

Power of the main frame(KW) | 37 | 160 | 200-220 | 250 | 280 |

Power of the classifier wheels(KW) | 7.5X3 | 15X4 | 15X5 | 18.5X5 | 18.5X6 |

Power of the fan(KW) | 22 | 132 | 185 | 200 | 220 |

Power consumption(main body, fan, classifier) | 38 | 38 | 32 | 33 | 33 |

Previous:没有了!