Welcome to Henan Zhongyide Intelligent Technology Co., LTD

Welcome to Henan Zhongyide Intelligent Technology Co., LTD

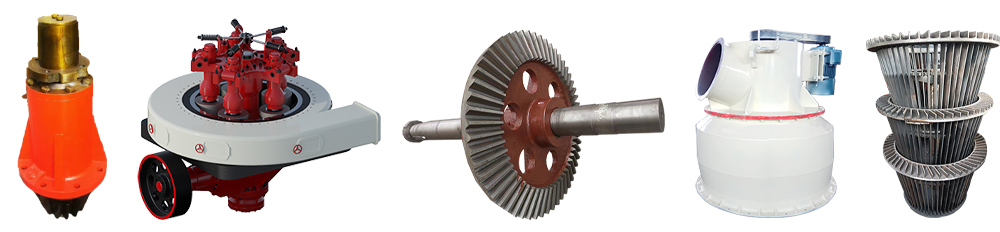

Product Center

CONTACT US

MTW Series European Pendulum Grinding Mill Introductions

The improved pendulum mill adopts series of new technologies such as integral bevel gear transmission, internal thin-oil lubrication system, curved air channel, etc. It is a high and efficient grinding product , which is widely used in power plant desulfurization , large non-metallic ore pulverization and building materials and chemical industry.

Suitable for grinding materials

Limestone, calcite, calcium carbonate, dolomite, barite, talc, gypsum, pyroxene, quartz, sodium bentonite, calcium bentonite, bauxite, marble, feldspar, phosphate rock, coal powder, clay, kaolin, wollite, lime, alumina, etc. Any materials which are Moh’s hardness below 7 andhumidity within 6% of all kinds of non-flammable and non-explosive materials are suitable.

MTW Series European Pendulum Grinding Mill Working Principle

The crushed materials below 35mm are sent into the main machine chamber quantitatively and continuously by the variable frequency belt feeder. Then the materials after grinded are into the separator by the fan air flow for classification. Under the action of the analyzer, the materials that do not meet the fineness requirements falls into the grinding room for re-grinding, and the qualified materials enter the cyclone powder collector with the air flow through the pipeline for separation and collection. The fineness powders are discharged by the discharge device. The equipment systems are equipped with a pulse dust collector, which strictly follows the requirements of environmental protection.

European Pendulum Grinding Mill features

1.The mainframe grinding is equipped with linkage balance pressure device, which is automatically pressurized and make the machine run more stable. This device also has the function of improving the grinding pressure between roller and the ring through adjusting the spring tension,so the capacity is stable and 30% higher than the traditional mills.

2.Roller assemblies lubrication use the intensive lubrication,which save the maintenance time and avoid bearing necrosis because of Untimely refueling, so it make the machine have longer lifetime.

3.Roller bearing room adopts multi-level labyrinth type overlapping forced seal structure, supporting multi-layer sealed cover, this structure and the sealed cover avoid dust into the roller assembly inside, extending the service life, reducing the cost of maintenance.

4.Bearing locking device which is self-developed protects the sealing and the bearing better.

5.All the bearings are lubricated by the oil pump attached at the bottom of the main shaft, the lubricating system will start and off along with the mill. At the same time, water cooling device is adopted to significantly improve the service life of the main bearing system

6.We use high-elastic rubber to connect the main and separator, removing the machine resonance and the noise, delaying the lifetime.

7.High accuracy Blade separator or Squirrel cage separator can be selected according the custom’s different demand, significantly improving the capacity,the precision of powder selection and the final fineness。

8.Equipped with energy-efficient blower and Petal type air intake, when operating, workers adjust the air volume precisely and conveniently.

9.According the custom demand, automatic or manual lubrication devices can be equipped which can save the maintenance costs.

Model | MTW115 | MTW130 | MTW145 | MTW160 | MTW178 | MTW198 | MTW218 | |

Roller pieces(pcs.) | 4 | 4 | 4 | 4 | 4 | 4 | 5 | |

Mainframe speed(r/min) | 125-135 | 105-120 | 95-105 | 82-100 | 75-95 | 65-75 | 62-72 | |

Feeding size(mm) | ≤25 | ≤30 | ≤30 | ≤30 | ≤35 | ≤35 | ≤35 | |

Fineness of final powder(mm) | um | 1600-45微米,最细可至38微米 | ||||||

mesh | 10-325目,最细400目 | |||||||

Capacity(t/h) | 4-15 | 6--20 | 8-25 | 9-30 | 11-35 | 12-40 | 15-50 | |

Main engine power (KW) | 45 | 75 | 110 | 132 | 185 | 220 | 315 | |

Dimension(m) | 6.0×5.5×8.2 | 8.9×6.7×9.5 | 9.7×8.4×11.2 | 8.3×9.7×9.6 | 10.3×9.7×10.4 | 12.5×9.5×11.4 | 13.4×12.7×11.7 | |

Notes:

1. The capacity is for grinding calcite( CaCo3>98%),200 mesh and passing rate is up to 80%.

2.The power indicated in the table changes with the change of physical properties of the grinding materials, and the actual equipped power is subject to the contract;

3.Any change of technical data shall not be advised additionally.